- Shandong Loyal Industrial Co.,Ltd.

- Промышленная микроволновая печь Машина пищевого экструдера Машина для производства печенья

High Quality Low Cost Corn Puffs Snack Food Extruder Machine

Corn puff making machine uses corn, broom, rice, wheat, oats, rye, corn grits, millet, bean grits and powders, sorghum, yellow rice, flour and other grains as materials to produce extruded snacks.

The corn puff making machine can obtain different puffed food by changing different moulds. The size of the finished product can be adjusted according to the different requirements of customers.

Loyal corn puff snacks production line adopt twin-screw extrusion technology and are highly flexible. .The product shape of corn puff making machine is determined by a combination of the die aperture, including ball, tube, stick, ring, fruit loop, star, wheel and flower etc.

Loyal corn puff making machine can produce various uncoated, coated or filled cereal based snacks – with a wide variety of recipes and shapes.

|

List Of Corn Puff Making Machine Technical Parameter |

||||

|

Machine Series |

Installed Power |

Power Consumption |

Output |

Size (L*W*H) |

|

LY65 |

84kw |

59kw |

120-150kg/H |

21000x1200x2200mm |

|

LY70L |

132kw |

92kw |

200-250kg/H |

23000x1500x2200mm |

|

LY85 |

239kw |

167kw |

300-500kg/H |

28000x3500x4300mm |

|

LY75 |

186kw |

139.5kw |

400-500kg/H |

24000*2000*2800 |

|

LY95 |

295kw |

222kw |

800-1200kg/H |

31000*3500*4300 |

Corn Puff Snacks Production Line

Отправить запросSorry! No matches were found.

How do they make puffed corn snacks?

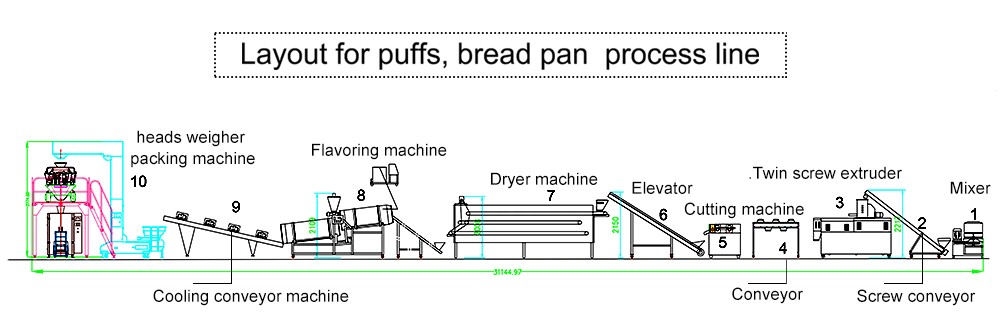

flow chart: mixer → screw conveyor → screw extruder → shaping machine → elevator → oven → seasoning line → packaging machine

Extruded maize snacks are manufactured through extruding moistened maize meal under high pressure and temperature conditions. The puffed product is then fried and usually coated with a savoury flavour such as cheese, chilli, barbeque sauce, sour cream or onion. The flavouring agent is applied in a powder form.

Loyal Snack Machines feature innovative technology developed through years of experience delivering snack food systems around the world.

We have 20 food engineers who have been engaged in the development of snack machinery for a long time, and can provide stable technical support and formulas all year round.

Any popular puffed snack production process can be delivered quickly!

And keep the taste!

| CORN PUFF SNACKS PRODUCTION LINE | |

| NO. | MACHINE OF CORN PUFFED SNACKE MAKING MACHINE |

| 1 | Flour Mixer |

| 2 | Double Screw Extruder |

| 3 | Air Conveyor |

| 4 | Multi-Layers Dryer (Electrical Type) |

| 5 | Multi-Layers Dryer (Gas Type) |

| 6 | Flavoring Machine |

| 7 | Cooling Conveyor |

| 8 | Molds Of Extruder |

| 9 | Control Cabinet Of Extruder |

| 10 | Control Cabinet Of Oven |

Technologies and Equipment in Processing Snack Foods

Loyal corn puff snacks production line manufacture of extruded snacks, cereals and inclusions. Partnering with our customers and suppliers, we are able to develop extruded items in a variety of shapes and flavors.

Small-pillows

Extruded Filled Pillow Puffs

A crisp shell hides the soft filling within; these pillows are intense! The flavor combinations of shell and filling are endless and can range from cheese to chocolate, savory to sweet.

Extruded Crispy Chips

Our versatile process can make chips in a variety of textures, flavors and shapes. From a tortilla-style massa triangle to a wasabi rice crisp, this chip is fully customizable.

Smallsticks

Extruded Snack Sticks

Made with real potatoes, these sticks are like french fries that are great for snacking anytime. Just don't limit this concept to french fries; think sweet potato, carrot or even purple corn sticks.

Smallrounds

Extruded Other Puffed Shapes

Balls, curls, bubbles, tubes, bananas, cups, disks, stars and more, we want to make your next big idea a reality.

Is puffed food healthy?

Puffed means that the volume will become larger, puffed food specifically refers to the use of frying, extrusion, frying, baking, microwave technology as a maturation process, before and after the maturation process, there is a significant increase in the volume of food.

Loyal puffed food equipment has a number of national patents in China.

Is puffed food good for us?

Healthy puffed food helps digestion, allows rapid pasting of starch in cereals and improves hydration of proteins and carbohydrates.

Use puffed foods as a snack. Don't eat too much, otherwise, it will soon lead to obesity or other things.

|

Technical Parameter Of Corn Puff Snacks Production Line |

|

|

Corn Puff Manufacturers Equipment |

Technical Parameter |

|

Flour Mixer |

Model:Ly-M |

|

Input Voltage:380v/50hz |

|

|

Installed Capacity:4kw |

|

|

Power Consumption:4kw |

|

|

Output:25kg/7minutes |

|

|

Size:1.3 X 1.0 X 1.2m |

|

|

Functions:Mixer Makes The Raw Material Adding To Water And Other Chemical Additive Fully Mixed |

|

|

Features: 1. This Part That Contacts Mixer To Material Adopts The Stainless Steel Material. |

|

|

2. The Discharge Hole Adopts The New Handle-Opened Design, Good Seal And Avoids Leaking The Material. |

|

|

Corn Puff Making Machine |

|

|

Corn Puffs Snack Food Extruder Machine |

Capacity:120-150kg/H |

|

Main Motor:22kw |

|

|

Heating Power:10kw |

|

|

Feed Motor:0.75kw Frequency |

|

|

Cutting Motor:0.75kw Frequency |

|

|

Oil Pump: 0.37kw Frequency |

|

|

Screws Material:38crmoal/38 |

|

|

Screw Diameter:65mm |

|

|

Screw Length:1050mm |

|

|

Barrel Material:45#Customize Steel |

|

|

Motor Brand:Lijiu Special Brand( China Famous Brand) |

|

|

Dimension:2500*930*1850mm |

|

|

Function:- Rice Powder, Corn Powder, Millet Powder, Wheat Powder, Oats, Buckwheat, Bean, Starch, Etc. |

|

|

Series Of Double-Screw Extruder Mainly Consist Of Feeding System, Extruding System, Cutting System, Heating System, Lubricating System And Controlling System. |

|

|

Automatic Lubricating And Forced Cooling Make Sure That Extruder Performs Safely And Extends Using Life. |

|

|

Feeding System, Extruding System And Cutting System All Adopt Frequency Conversion Timing To Gain Powerful Drive, Stable Perform, And Electricity Saving. |

|

|

Air Conveyor |

L Screw Are Made Of Alloy And Processed By Special Technique To Possess High Intensity, Abrasion Resistant And Longer Using Life. |

|

Model:Fsj-Ii |

|

|

Input Voltage:380v/50hz |

|

|

Installed Capacity:0.75kw |

|

|

Power Consumption:0.75kw |

|

|

Output:100-300kg/H |

|

|

Size:1.2×0.6×2.3m |

|

|

Used To Carry Products To The Next Device. |

|

|

3-Layers Oven |

3 Layer, Electric Type |

|

Capacity:100-150kg/H; |

|

|

Installation Power: 45kw |

|

|

Driving: 0.75kw |

|

|

Heating Power:44.25kw |

|

|

Dry Time: About 20 Minutes |

|

|

Dimension: 5200*1200*2300mm |

|

|

Weight: 1200kg |

|

|

For Dryer: Aluminum Silicate As Thermal Insulation Materials Inside The Body Cover |

|

|

This Kind Of Oven Has A Wide Range Of Application. It Can Dry All Shapes Of Puffing Food, Including Strip, Lump, Granular Materials Etc, As Well As Other Types Of Materials. Users Can Choose Different Types With Different Layer, Length, And Heating Mode. |

|

|

It Has Compact Design And Easy Operation. |

|

|

The Oven Is Droved With Double Pitch Roller Chain And Heats Materials Circularly. It Runs Smoothly, Never Obstruction. |

|

|

Roasting Temperature And Time Can Be Adjusted, Effect Of Roasting Is Perfect. |

|

|

With High Efficiency Fuel Saving System, Reasonable Heat Distribution, Material Is Heated Equally, Low Energy But Large Output. |

|

|

Pre-Drying Machine(Gas Type) |

Model:Dlk3-Ii |

|

Input Voltage:380v/50hz |

|

|

Driver Power: 0.75kw |

|

|

Dehumidification Fan:0.55kw |

|

|

Circulating Fan:3kw |

|

|

Burner Brand: Italy Baltur |

|

|

Fuel Consumption: |

|

|

Diesel:5-16kg/H, |

|

|

Gas: 5-16m³/H |

|

|

Output:100-200kg/H |

|

|

Size:6100x1500x2600mm |

|

|

Functions: |

|

|

It Is 3 Layers Oven. It Can Be Used To Bake And Dry The Food. The Oven Can Bake All Kinds Of The Inflating Food, Pet Food, And So On. |

|

|

Features: |

|

|

1. The Oven Has The Compact Structure, Small Occupying, Large Drying Area, Small Surface Area, Slight Radiating Heat And High Thermal Efficiency. |

|

|

2. The Belt And The Heat Preservation Use The Stainless Steel; It Is Suitable For Food Industry. |

|

|

3. The Running Speed Of Belt Net Can Be Controlled (Frequency) |

|

|

4. The Temperature Can Be Controlled Willfully And Designed According To The Need. |

|

|

5. Heat With Infrared Ray Heating Tube, Raise And Lower Down Temperature Quickly, Small Heat Inertia And High Heat Efficiency. |

|

|

6. Adjustable Transit Speed Of Net Belt With Accurate Temperature Control Device. |

|

|

7. Double-Roller Chain And Chain Drive Make Stable And Smooth Running. |

|

|

8. Sliding Board Bottom Of Dryer For Easy Cleaning. |

|

|

9. Suitable To Dry Non-Fried Extrusion Snacks, Nutritional Powder, Bread Crumb, Pet Food, Soybean Protein, Etc. |

|

|

Octogonal Seasoner Flavoring Machine |

Capacity:60kg/H |

|

Power:0.75kw |

|

|

Size:1200×1100×1600mm |

|

Corn Puff Making Machine Process

- How About Puffed Cereal Corn Flakes Equipment? +

- How about puffed cereal corn flakes equipment? Breakfast cereal corn flakes, cereal flakes, and baked ready-to-eat oatmeal are a kind of crisp food, which can be eaten directly or brewed with yogurt or milk. It has good rehydration, does not rotten on the...

- What Are Consumers' Concerns About Puffed Snack? +

- In fact, many of our young people especially like to eat those puffed foods, like potato chips, biscuits, etc. Basically, as long as they eat them, they can't stop at all. However, there are still a lot of controversies about puffed food. Many people...

- What Should We Pay Attention To When Eating Puffed Snacks? +

- Puffed food tastes good, and many puffed foods have unique shapes and are loved by children. Here, Shandong Loyal Machinery Equipment Co., Ltd. reminds that puffed foods are good, but eating too much can affect your health. 1.The puffed...

- Why Choose The Twin Screw Puffed Food Extruder +

- Introduction of the twin screw extruder includes the impact of the micro-structure and physical and chemical properties of the raw materials after extrusion, the performance of the extruder and the characteristics of the raw materials themselves on...

- What is the difference between fried food and puffed food? +

- Fried snacks and puffed snacks are common foods in life. The two are very similar and have a lot in common. Faced with a variety of snacks, it is often difficult to distinguish whether they are puffed snacks or fried snacks. In fact, there is still a...

- Puffed Dog Food Machine Complete Equipment +

- The whole set of puffed dog food machine can adjust the raw materials, temperature, moisture and other process parameters, so that the product has the characteristics of novel shape, unique taste, rich nutrition, and delicate organization, which is...

- Why Is Corn Puffed? +

- Animal feed: suckling pig feed. The suckling pig feed contains 60% or more corn ingredients. It is ideal to expand all corn ingredients. But it will lead to a sharp increase in production costs. The conventional method is to medium-expand half of the corn...

- What Are The Equipment For Puffed Breakfast Cereal Corn Flakes? +

- Introduction: Breakfast cereal corn flakes, cereal crisps, baked instant oatmeal are a kind of crisp food. It can be eaten directly dry or brewed with yogurt or milk. It has good rehydration, does not rot away from the outside, has a smooth taste, and has...

- Food Puffing Snack Machine -- Visit From British Customers +

- Puffed food is a new type of snack developed in the world in recent years. Through the processing of puffed equipment, a variety of food with delicate appearance, rich nutrition, and the crispy and fragrant taste is produced. Therefore, a broad category of...

- Can't We Eat Too Much Puffed Food? +

- Many of us always like to eat some puffed food when we are bored. Whether they are elderly or children, or even young people, they like to eat these potato chips, shrimp chips, corn sticks and so on. Like a young man, he opened a pack of puffed food...

Corn Puff Making Machine Video

- Advantages Of Puffed Food +

- The preservation rate and digestibility of nutrients are high. The protein-rich plant material expands into high temperature and short extrusion, the protein is completely denatured, and the tissue structure becomes porous, which is conducive to...

- Features Of Puffed Food Which Produced By Twin Screw Extruder Puffed Food Making Machine +

- Puffed food has the following characteristics: 1. The preservation rate and digestibility of nutrients are high. The starch in the cereal raw materials is quickly gelatinized during the full automatic puffing snacks processing line, which...

- What Are The Advantages Of Food Puffing Equipment? +

- In recent years, a series of snack foods have been produced by puffing machinery and equipment at home and abroad. And they are crisp and refreshing, easy to digest and absorb, and are favored by consumers. Food puffing making equipment has also...

- Do You Know The Maintenance Of The Puffed Snack Making Machine? +

- With the continuous progress and development of society. Extruder machine is used more and more widely. Then the maintenance and maintenance of the corn puff extruder machine becomes more and more important. Next, Shandong Loyal will explain to...

- What Is The Working Principle Of The Corn Puffing Machine +

- With the continuous progress and development of society, the use of industrial corn extruder puffing machine is also increasing. What is the working principle of corn extruder machine? Let me explain to you: ...

- Do You Know The Adaptability Of Food Puffing Machinery? +

- With the continuous progress and development of society, twin screw puffed machinery is used more and more. During the use process, do you know the adaptability of automatic puffed machinery? Let me explain to you: Scale suitability. According to...

- Introduction And Maintenance Methods Of Puffed Snack Equipment +

- Everyone is no stranger to puffed snacks. And everyone knows puffed foods. Nowadays, there are many different puffed snacks in large and small supermarkets. Most of which are made using puffing mechanism. With the continuous development of puffed...

- What Are The Precautions When Installing Puffed Snack Machinery? +

- Puffed snack making machine is an efficient and high-performance food machinery. In order to make newly purchased machinery and equipment capable of stable and efficient production, correct installation is very important. For...

- What Is The Correct Way To Use Puffed Snack Making Machinery? +

- How should the automatic puffed snack making machine be used correctly in the work to ensure the safety and the service life of the puffed food machinery and equipment? Next, Loyal will explain to you the correct use of puffed food machinery:...